Take the fast track to Active Heave Compensation

with Scantrol’s off-the-shelf AHC solution

Configure to match your application, test, and tune yourself at a fraction of the cost.

Advantages of Scantrol AHC

Heave motion caused by waves and wave motion can affect offshore installations and lifting operations. Scantrol AHC actively compensates for vessel movement to keep the load stable, ensuring safer and more efficient offshore operations in all sea states.

No Need for Expensive Sea Trials

Save cost on engineering, hardware, installation and commissioning.

No Need for a Specialist

Integrate yourself.

No programming needed.

Test and tune at dockside.

Free OTA Assistance

Free Over The Air assistance, maintenance, and training for integrators, commissioning engineers, and operators.

No Hidden Costs

Affordable AHC control systems for winches, cranes and cylinders.

Ranging from 500kg to 500tonne.

mTrack AHC Controller - World’s most affordable and easy to integrate AHC Solution

• Off-the-shelf AHC controller with integrated motion reference unit (MRU).

• A game-changer that makes AHC affordable even for smaller winches and cranes used for subsea operations.

• Includes all the tools you need for easy installation and commissioning, no need for expensive experts.

Marine & Subsea Applications

Active Heave Compensation for ROV Operations

Increase the weather window of your ROV operations with an AHC system that stabilizes the TMS and provides safe docking even in bad weather conditions. Scantrol AHC can be retrofitted to a wide range of existing LARS systems used in offshore installations, ensuring stable control of the load even under strong wave motion.

Active Heave Compensation for Offshore Cranes

It is widely accepted that heave compensation improves performance for large offshore cranes and other lifting equipment. mTrack makes it affordable to utilize this advantage even on smaller cranes and hydraulic winches used in offshore operations.

Active Heave Compensation for Intervention Operations

Scantrol AHC combines winch and cylinder control to ensure safe and effective intervention operations. The integrated motion reference unit (MRU) allows for precise motion control and reduces the impact of waves during demanding subsea work.

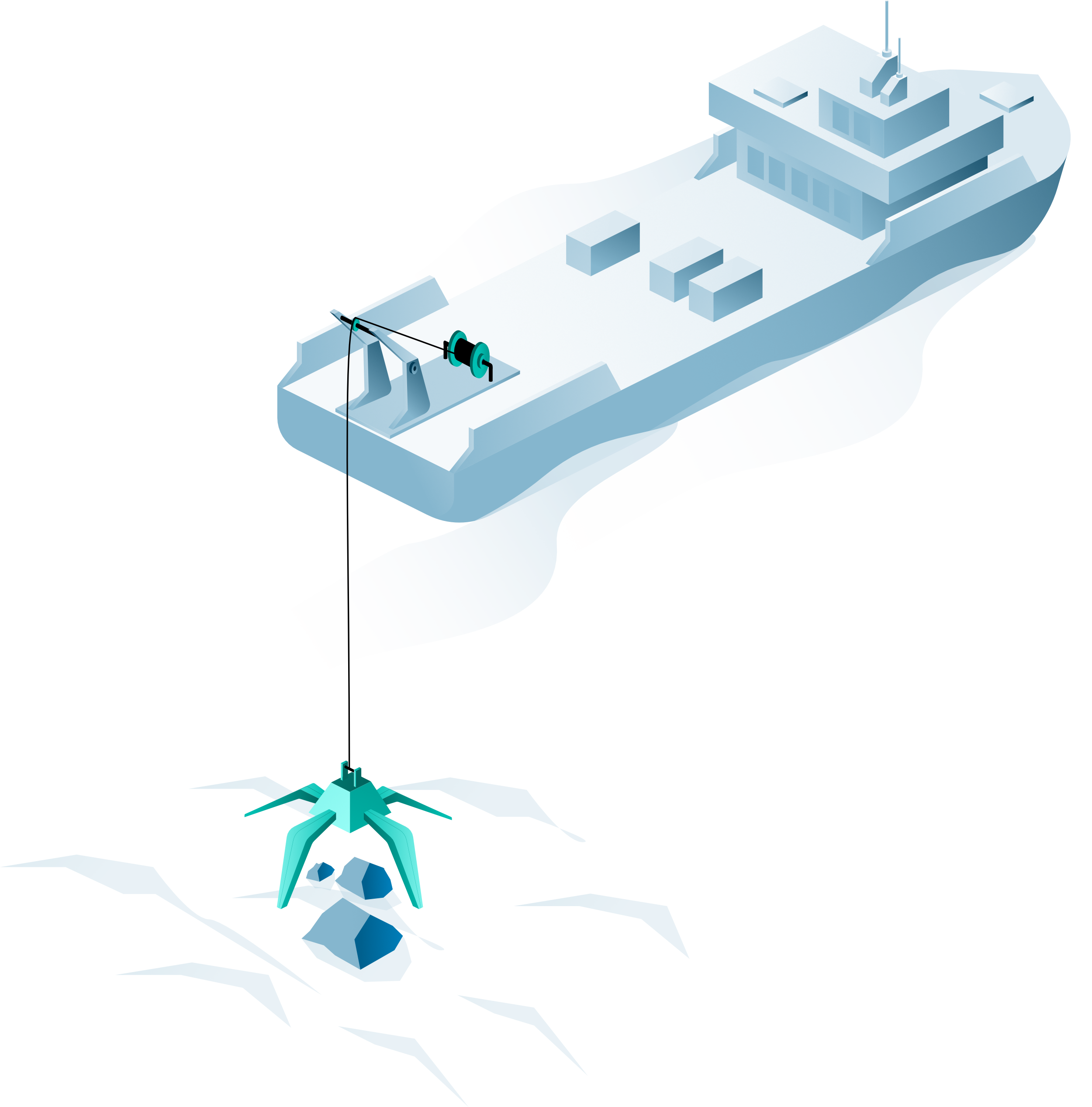

Active Heave Compensation for Boulder Clearance

Get full control of your grab and other salvage equipment in all weather conditions. The heave motion compensation ensures smooth lifting and accurate control of the load, minimizing strain and increasing operational uptime across various offshore installations.

Active Heave Compensation for Drilling Operations

Scantrol AHC adds accuracy to your passive heave compensation system and secures optimum bit weight and displacement control when drilling in varying structures. This makes it ideal for drilling and coring operations, where stability and control of the load are critical for efficiency and safety.

Marine Research Applications

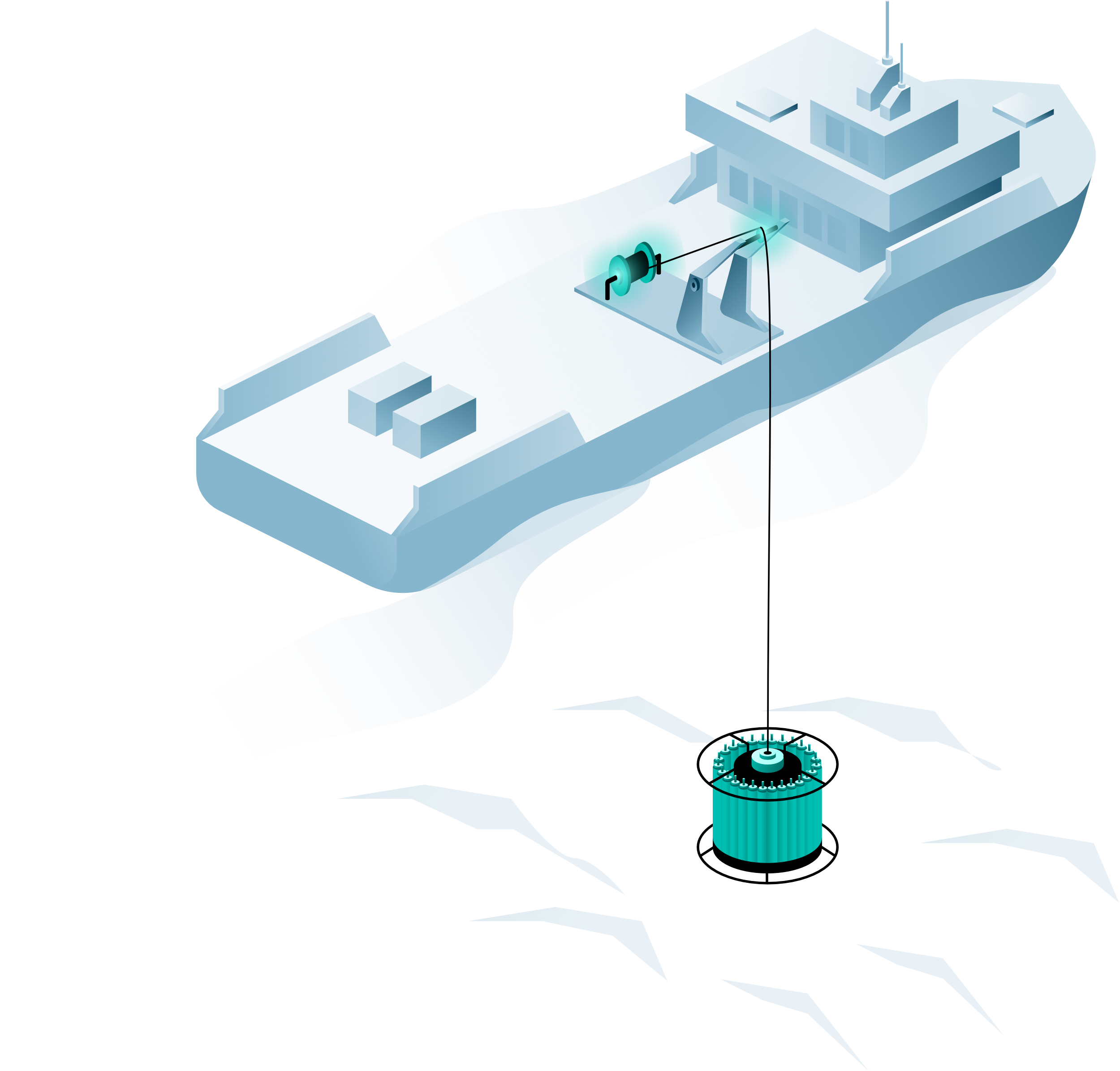

Active Heave Compensation for Collecting Scientific Data

Most data sampling equipment is affected by vessel heave motion and wave motion. Scantrol’s heave compensation systems improve data accuracy and ensure reliable sampling results even in rough sea conditions, enhancing marine research performance.

Active Heave Compensation for Towing Operations

Whether you are towing a sonar or other survey equipment, Scantrol AHC will keep it stable at a certain depth or follow the seabed profile. The system maintains consistent performance in offshore operations and enables stable, efficient towing regardless of waves or passive systems used.

What our Customers are Saying

“With Scantrol AHC, the ROV pilot is able to maintain the position of the TMS unit while focusing on docking and undocking the ROV, preventing any risk of damaging the delicate tether, which is the lifeline of any ROV system”

- William Lee, Managing Director, Fugro Subsea Technologies

“Operating in Brazil on our first job has been met with many environmental challenges, but thanks to the design and robustness of the LARS systems and superb AHC, we continued operating in sea conditions usually too extreme for today’s ROV systems”

- Tony Manocchio, ROV Superintendent, EMAS AMC

Add Value to your New Winch with Scantrol AHC

The easiest way to add AHC is by connecting the mTrack controller to your own winch control system. If you need a complete control package, Scantrol can deliver that as well.

We offer free design support for active heave compensation systems, including:

• Guiding on AHC requirements for specific applications.

• Advice on selection of hydraulic winches or electric drives and components.

• AHC Analyzer for calculation of AHC performance and required power, speed, and torque.

How to Retrofit mTrack to Existing Winches

Many winches are suitable for AHC operation, reuse of your winch represents a major cost reduction compared to buying a new winch and results in a reduced carbon footprint. We can help you determine if your winch is suitable for AHC.

Is there anything you would like to discuss or learn more about?

Fill out the form below or contact Suzy

Suzy Zhu

International Sales Manager

Email: suzy@scantrol.com

Phone: +47 465 20 370