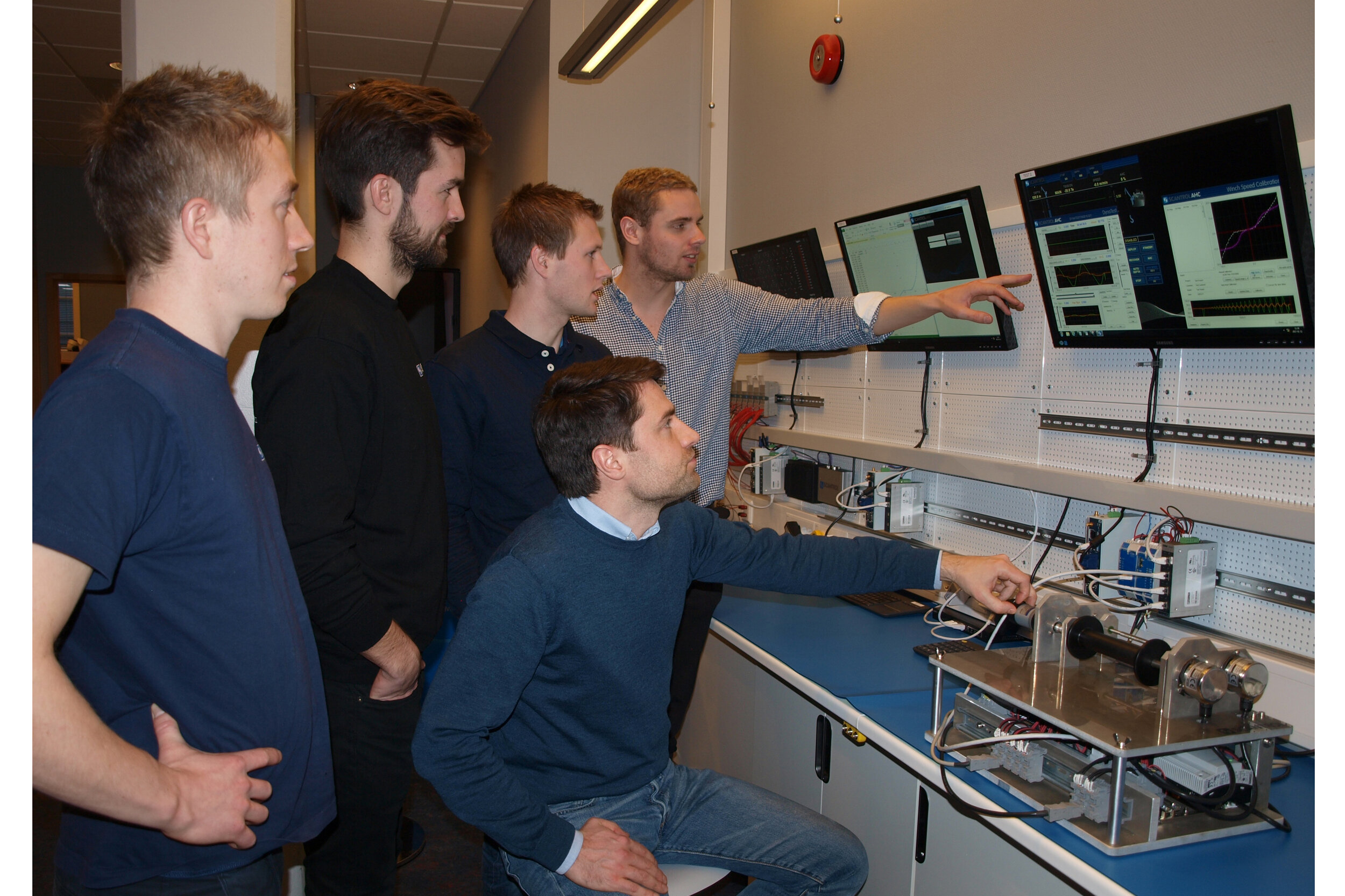

Scantrol R&D Team Develops AHC Technology Geared For The Future

— “Our development team has spent a lot of resources on making our Active Heave Compensation (AHC) systems more available, cost-effective and efficient to commission”, says Senior Design Engineer, Espen Karlsen.

The service engineers at Scantrol are pleased that about half of the commissioning time has been reduced.

By the time Scantrol commissions AHC system number 100, probably by the end of this year, the development team expects to have a full Auto-tuning function as an integrated part of the software in order to make optimization of the system even more efficient.

Focus on user value – making AHC more available and cost-effective

User value is important to Scantrol and the company is focusing its development resources on making AHC technology available for more winch- and crane manufacturers.

In order to fulfill this goal, it has been essential for the R&D team to develop standard solutions of high quality and to reduce time spent on commissioning by adding smart tools to the software. This combination has resulted in an increased volume of systems and lower cost for the customers.

— “One of our most recent commissions was done in only 3 days due to the improvement of existing products. Efficient testing, tuning, commissioning, and easy access to remote support is crucial in order to offer cost-effective and time-saving AHC systems to companies worldwide”, explains R&D Manager, Dr. Darren Hammersland-White.

The development team, Darren with a Ph.D. in Computer Science and Espen with a master in Electronics, has over the years built up a lot of competence on AHC technology and the advantages of using it.

Together with weather-related downtime, time spent on mobilizing big cranes can be expensive and time-consuming bottlenecks for the ship owners. These challenges can be remedied by using one of Scantrol’s latest applications, the AHC Link.

This application makes it possible to share resources from an existing AHC system with other subsea systems onboard the same vessel. AHC Link allows multiple subsea systems to share some of the components, such as the vessel motion sensor.

This will reduce the installation costs and save time spent on equipment mobilization, making the system even more desirable for the client.

Developing the new generation monitoring and control systems

With nearly 100 AHC systems delivered to date, Scantrol has built up a considerable reservoir of expertise. This knowledge is being consolidated into a new automation software platform called Blueline. This system includes a streamlined modern user interface that facilitates easy calibration, configuration, verification and operation of active heave compensation system (AHC).

This system further minimizes engineering and commissioning time making AHC systems more affordable and easier to operate for our customers. The product line will gradually be introduced during the year.

Software quality control – key to long-term success

—Scantrol has delivered control systems for the last 30 years. During this time our expertise has been consolidated into standard solutions. This has been key in keeping engineering time down and passing on those savings to our customers, explains Dr. Hammersland-White.

Scantrol commonly has systems in operation for over ten years. During this time customers receive updated functionality while backwards compatibility is maintained. Control of software that has long life time cycles is a challenge yet Scantrol maintains total control through rigorous use of version control and platform migration.