14 AHC Systems For Fugro

Scantrol is proud to announce an order from Fugro for four mTrack AHC controllers with integrated MRU.

– We are proud to once again be the preferred AHC supplier for Fugro. This new order of four mTrack AHC controllers means we have supplied a total of 14 systems to Fugro. Repeat orders from such a major player in the business shows that our products are of high quality and add value for customers and end users, says Rolf Hjelmeland, Business Development Manager for Scantrol AHC solutions.

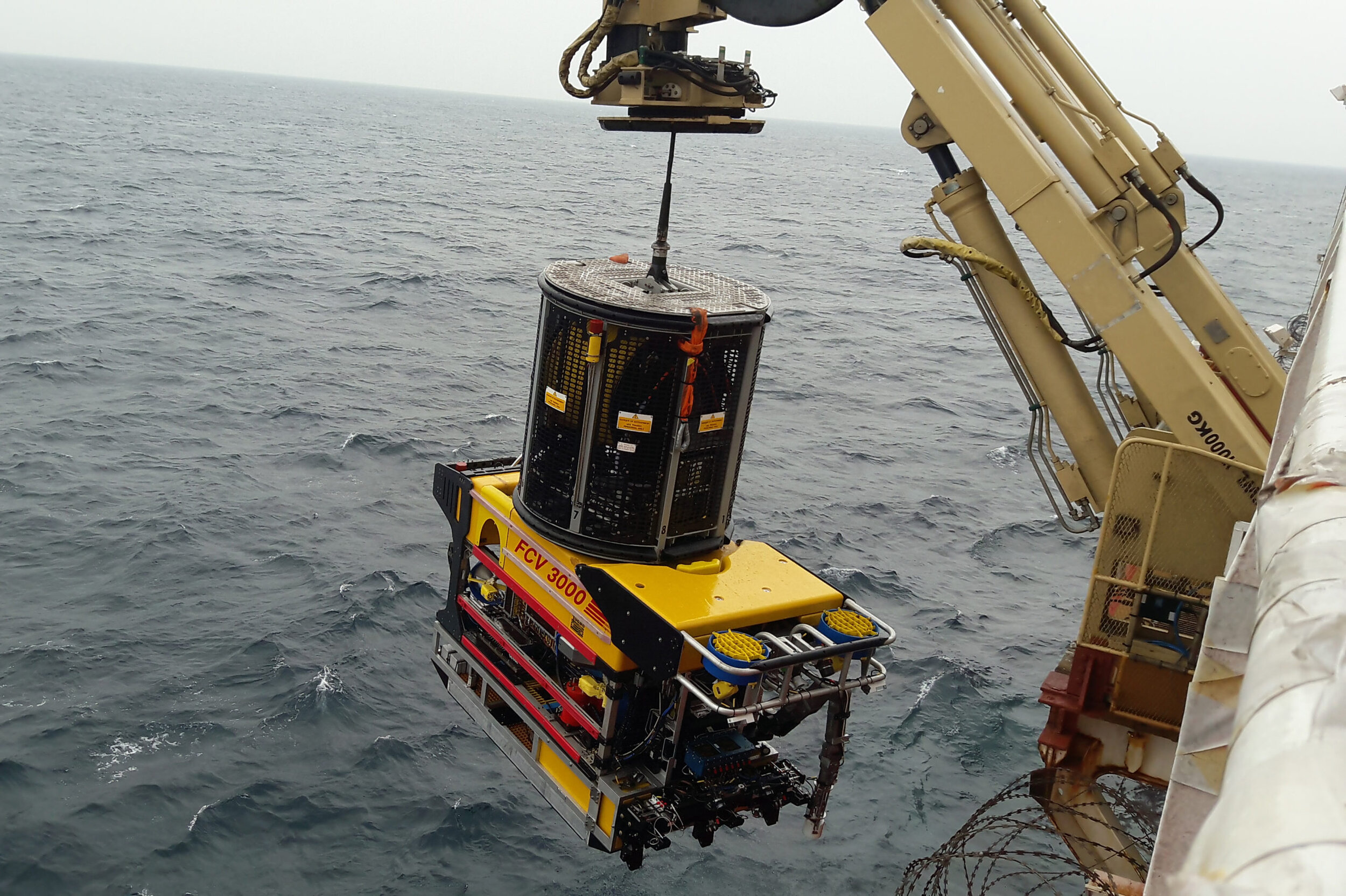

Over the past few years, Scantrol and Fugro have been working closely to find the best solution for their LARS systems. Since the first system was supplied, there has been a lot of development. Fugro has already taken the new mTrack AHC controller in use for one of their systems and is already experiencing the benefits. Mucktar Li, Senior Electrical Engineer at Fugro’s ROV Production and Support Center in Singapore, is impressed by the functions and features of the mTrack AHC controller:

– Many improvements have been implemented for users since we received the first two AHC systems integrations. The system has become much simpler for users. Having reviewed the GUI outlook, I can confirm that the work put in from Scantrol is “top notch”.

Worldwide online training

Customer training has always been important to Scantrol. Our philosophy is that our customers save time and money when they are trained to manage integration and support of the Scantrol control system.

–Fugro is a great example of the benefits of training and they have done most of the integration on their own since the first system was delivered, based on basic training courses, explains Hjelmeland.

Previously, Scantrol has typically provided training onsite in Singapore. However, due to the Covid-19 travel restrictions, the most recent training was delivered online, whereby 20 people from different parts of the world participated remotely.

– We have excellent training and test facilities; a winch with different characteristics, complete control systems and mTrack on our local network, and a platform for simulating the vessels movement in the sea. This, combined with remote support, makes it easy for Scantrol to offer efficient online training, explains Hjelmeland.